Analysis of related parameters of metal spiral wound gasket

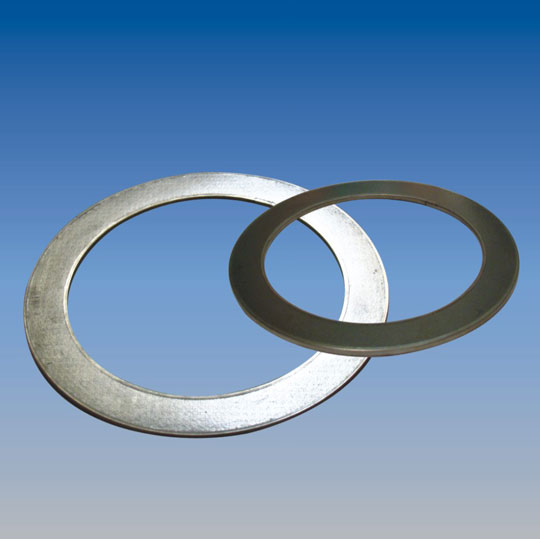

Metal winding gasket is made of metal corrugated paper tape and non-metallic tape alternately, spirally wound, and can be added in the working environment. Due to the advantages of multi-channel sealing, high temperature resistance, corrosion resistance and low surface roughness, flange seals are widely used in petrochemical industry, valves and other industries. Applicable medium:

Steam, natural gas, cracked gas, oil, acid, alkali, salt solution, etc.

Advantages:

1, good compression and elasticity.

2. It has proper plasticity, can adapt to uneven sealing surface after compression, and fills the gap of the sealing surface to ensure good sealing performance under the condition of alternating system temperature and pressure. Application range of metal spiral wound gaskets: sealing of flange joints of pipelines, valves, pressure vessels, condensers, heat exchangers, towers, manholes, hand holes in petroleum, chemical, metallurgy, electric power, shipbuilding, machinery and other industries.

3. Good mechanical properties such as tensile strength and elongation. The structural density of the metal spiral wound gasket can be made according to different locking force requirements, and the inner and outer steel rings are used to control its maximum compression. The surface accuracy of the flange sealing surface contacted by the spiral wound gasket is not high. The metal spiral wound gasket is especially suitable for occasions where the load is uneven, the joint force is easy to relax, the temperature and pressure change periodically, and there is impact or vibration. Spiral wound gaskets are the original static seals for flange connection processing of valves, pumps, heat exchangers, towers, manholes, and hand holes.

4 has good corrosion resistance, will not be destroyed in some extreme media, and will not produce large expansion and contraction. The structural density of the metal spiral wound gasket can be made according to different locking force requirements, and the inner and outer steel rings are used to control its maximum compression. The surface accuracy of the flange sealing surface contacted by the spiral wound gasket is not high. The metal spiral wound gasket is especially suitable for occasions where the load is uneven, the joint force is easy to relax, the temperature and pressure change periodically, and there is impact or vibration. Spiral wound gaskets are the original static seals for flange connection processing of valves, pumps, heat exchangers, towers, manholes, and hand holes.

5. Creep is not softened at high temperature, and it is not hardened and contracted at low temperature.

6 has sufficient strength, can not be crushed under the action of external force, nor can it explode under high pressure.

扫码关注我们

扫码关注我们