Knowledge analysis of metal spiral wound gasket

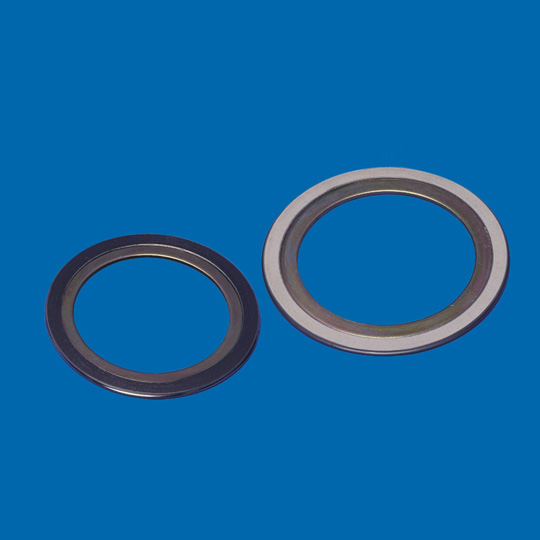

Metal wound gasket product structure is not too complicated, so it is actually easier to operate in the project. The structural density of the metal spiral wound gasket can be made according to different locking force requirements, and the inner and outer steel rings are used to control its maximum compression. The surface accuracy of the flange sealing surface contacted by the spiral wound gasket is not high. The metal spiral wound gasket is especially suitable for occasions where the load is uneven, the joint force is easy to relax, the temperature and pressure change periodically, and there is impact or vibration. Spiral wound gaskets are the original static seals for flange connection processing of valves, pumps, heat exchangers, towers, manholes, and hand holes. Another benefit is that during the disassembly process, it will not be damaged often and will not get dirty for a period of time. During the actual use of the project, it will not cause damage to other components. It will also be used in Japanese aircraft carriers and will not corrode the flange sealing surface. And it has higher strength. Metal-coated gaskets cover stainless steel, copper, carbon steel and other metal materials such as flexible graphite, asbestos, and PTFE. Working temperature: -200 ~ 650 ℃, working pressure: 3.5MPa, main application: suitable for sealing of pumps, valves, heat exchangers and various flanges. Pipeline, flange, valve, pump inlet and outlet, heat exchanger, reaction tower, observation hole, hand hole, high temperature, high pressure steam, oil and gas, solvent, gas, heat transfer medium, etc Seal the housing cover, etc.

Metal winding gasket is made of stainless steel tape, flexible graphite tape or asbestos tape, Teflon tape and other overlapping windings, welding end points. Application range of metal spiral wound gaskets: sealing of flange joints of pipelines, valves, pressure vessels, condensers, heat exchangers, towers, manholes, hand holes in petroleum, chemical, metallurgy, electric power, shipbuilding, machinery and other industries. The structural density of the metal spiral wound gasket can be made according to different locking force requirements, and the inner and outer steel rings are used to control its maximum compression. The surface accuracy of the flange sealing surface contacted by the spiral wound gasket is not high. The metal spiral wound gasket is especially suitable for occasions where the load is uneven, the joint force is easy to relax, the temperature and pressure change periodically, and there is impact or vibration. Spiral wound gaskets are the original static seals for flange connection processing of valves, pumps, heat exchangers, towers, manholes, and hand holes. A non-metallic fiber material (also called filler), which has good elasticity after a long time of pressing. Since the metal is wrapped in the outer layer, heat resistance is improved. The inner filler can avoid the leakage caused by the direct contact between the fiber and the medium, maintain good resilience, and thus improve the sealing performance of the product.

扫码关注我们

扫码关注我们